Martin Jakubec, Adam Tywoniak, František Štěpánek

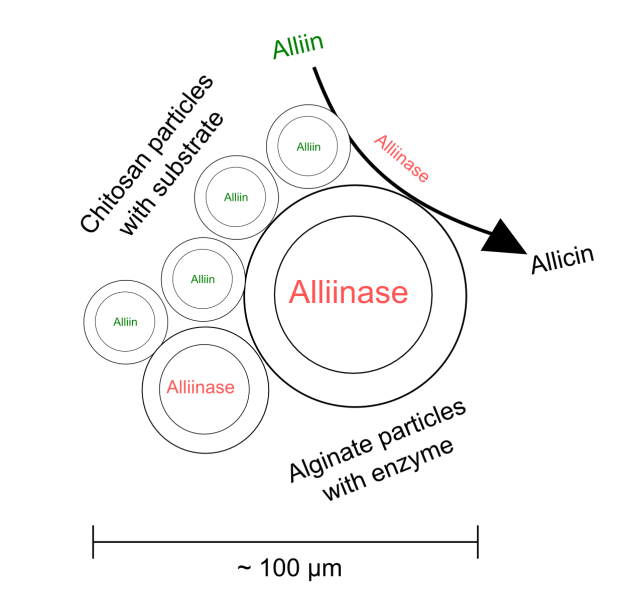

In the nature, there is a lot of substances, which are unstable and which are created just on demand in time, when it is desirable. The example of such a system could be the enzyme allinase and the substrate alliin, which are precursors of enzymatic reaction creating unstable antibacterial substance allicin. Alliin and allinase are separately located in garlic cells and only when a garlic cell is crushed they react together and produce allicin (which is also responsible for the typical garlic smell). In our ongoing work, we are trying to imitate such a system by separating alliin and allinase from fresh garlic and encapsulating these 2 substances into polymeric microparticles using a spray dryer BUCHI Mini-B290 and/or Encapsulator BUCHI B-395. Consequently, we are aggregating these two types of particles to form a “small biochemical reactor”, which is able to produce active substance allicin in situ.

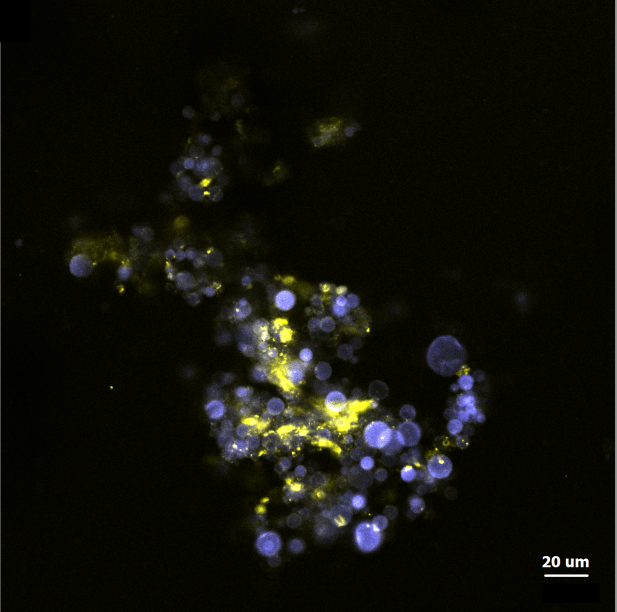

Laser scanning confocal microscopy image of aggregates composed of chitosan (blue) and alginate (yellow) particles at mass ratio 1:1

Publications

- Ullrich M., Hanuš J., Štěpánek F., “Remote control of enzymatic reaction in compartmentalized microparticles: a system for the delivery of unstable actives”, Chem. Eng. Sci. 125, 191-199 (2015)